Our Process

Our Banana Leather Creation Process

Banhide Banana leather, a sustainable alternative, begins with harvesting premium bananas. After extracting fibers from the banana plant’s stem, they undergo a refining process to eliminate impurities. These fibers are then combined, compressed, and dried to create a flexible and durable material. The sheets of banana fiber are treated with natural dyes or left in their organic state, offering versatile design options. Skilled artisans meticulously craft products, ensuring quality and style. Rigorous quality checks and eco-conscious packaging complete the process, providing an eco-friendly, cruelty-free, and stylish choice for conscientious consumers. Experience the transformation from banana plant to exquisite leather alternative with our innovative and sustainable production approach.

Join the Banhide Movement

Choose Banhide for products that are free from animal materials and harmful chemicals – a conscious and compassionate choice for sustainable and quality-driven fashion.

Join the Banhide Movement

Choose Banhide for products that are free from animal materials and harmful chemicals – a conscious and compassionate choice for sustainable and quality-driven fashion.

The Impact We Create

Banhide leads the way in water conservation, reducing water usage by up to 50% compared to traditional leather production.

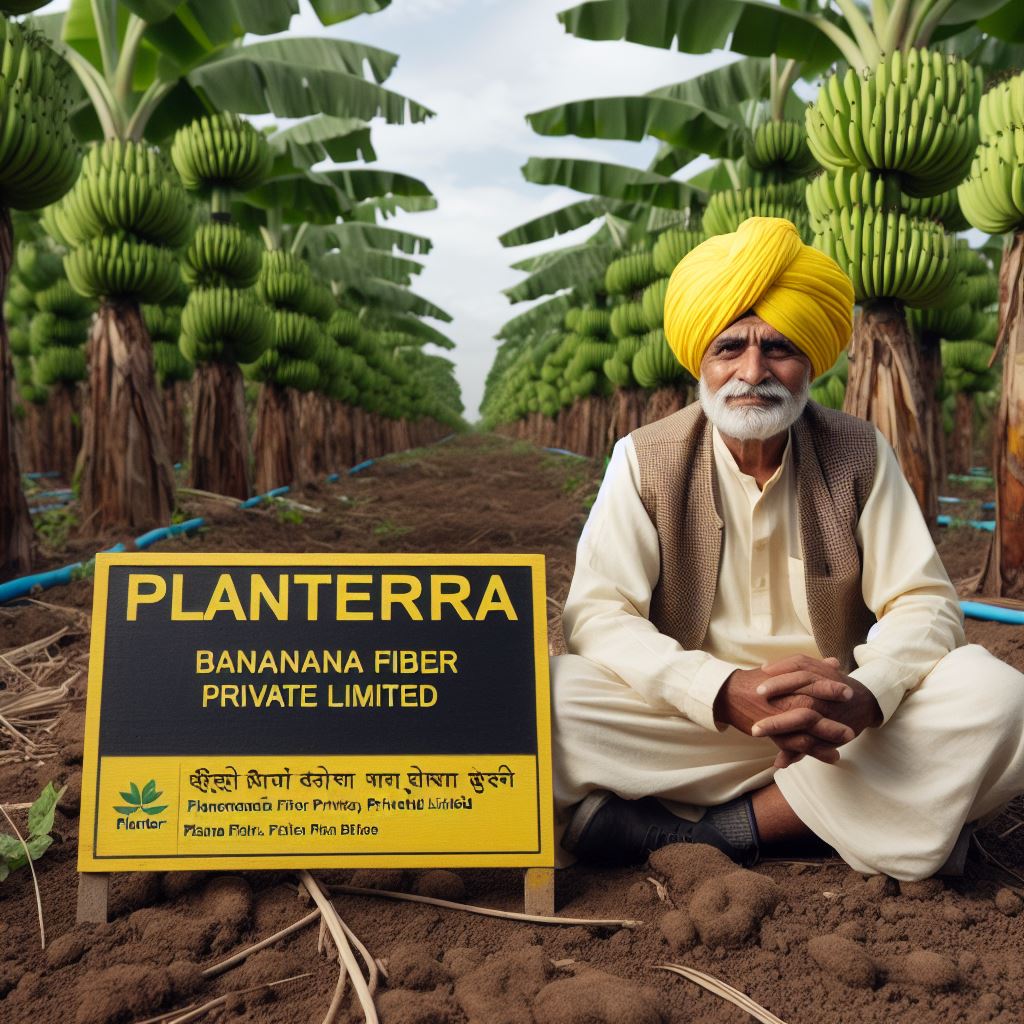

Your Planterra purchase plays a pivotal role in supporting farmers and their communities.

Approximately 80% of banana crop waste is upcycled in the production process

Choosing Banhide isn’t just a style statement; it’s a conscious decision that creates a significant impact. With Banhide Banana Leather, you contribute to water conservation, reducing usage by up to 50%. Your purchase supports farmers and their communities, fostering positive economic impact. Additionally, approximately 80% of banana crop waste is upcycled, promoting circular economy practices. Banhide isn’t just fashion; it’s a movement towards a sustainable and compassionate future. Join us in making a tangible difference with every stylish choice.

Market Opportunity of Plant Leather

The current market landscape craves vegan leather, but the intricate supply chains and production processes pose challenges for traditional animal leather manufacturers venturing into plant leather production. Furthermore, widely-used vegan alternatives like polyurethane and PVC, stemming from petrochemical sources, deter large-scale brands. Thus, our competitors predominantly consist of other bioleather companies. Plant leather producers currently face fragmentation, lacking a clear market leader.

Early entrants like Pinatex (pineapple leather), Dessrto (cactus leather), and Mylo (mycelium) have made strides with established partnerships. However, our distinctive approach, utilizing waste material instead of growing new resources like cactus and mycelium, positions us as a more sustainable and cost-effective choice. This uniqueness gives us the potential to outshine competitors in terms of price, quality, and overall sustainability.

Progress Made:

- We’ve successfully developed banana plant leather as a sustainable and cruelty-free alternative to traditional leather.

- We’ve established partnerships with local banana farmers to source the raw materials.

- Our production process has been refined to create high-quality banana plant leather that meets industry standards.

- Initial market testing has shown strong interest from eco-conscious consumers and fashion brands.

- We’ve trained a skilled workforce for various stages of production, contributing to job creation in our community

Plan Forward:

- Expand Production: Increase our production capacity to meet growing demand.

- Research and Development: Continue to innovate and improve the quality of banana plant leather.

- Market Expansion: Reach out to more fashion brands and retailers to promote our eco-friendly product.

- Sustainability Focus: Strengthen our commitment to sustainable and ethical practices.

- Job Creation: Hire and train more local workers, supporting economic growth.

- Global Reach: Explore opportunities to export banana plant leather to international markets.

- Consumer Education: Educate consumers about the benefits of banana plant leather and its positive impact on the environment.

By following this plan forward, we aim to make banana plant leather a mainstream and sustainable choice for consumers while contributing to the well-being of our community and the planet.

Further Progress plans

Second Year (2024)

Global Expansion Strategy: Extend operations to international horizons, engaging with a diverse spectrum of international buyers for B2B endeavours.

Enhanced Production Scale: Elevate manufacturing prowess to produce 1000 panels daily, accommodating burgeoning demand while ensuring quality.

Proprietary Product Line Debut: Introduce an exclusive array of plant leather products, fusing elegance with sustain ability for discerning consumers.

Uninterrupted Progress: Further amplify our initial achievements, solidifying our position as a trailblazing influence within the industry.

First Year (2023)

Establishing a Production Hub: Strategically identify and secure an ideal location for our compact manufacturing facility.

Initial Production Launch: Embark on production, crafting 200to400 sheets per day, an inaugural step showcasing our capabilities.

Ethical Certification Drive: Initiate the process for obtaining esteemed vegan and cruelty-free certifications, alongside essential

documentation.

Synergistic Partnerships: Collaborate with renowned Indian brands.

Orders Validation: Fulfill inaugural small-scale orders, validating market enthusiasm for our ethical and sustainable creations.